Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

What is a high temperature vacuum furnace?

What is the function of high temperature vacuum furnace?

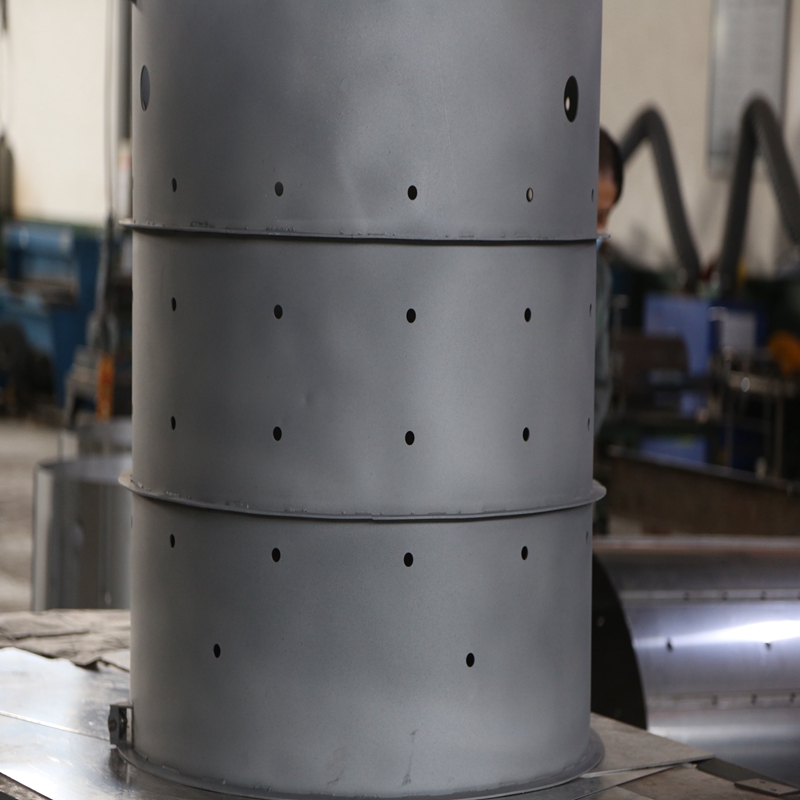

The high-temperature vacuum furnace uses a vacuum system (which is carefully assembled by components such as vacuum pumps, vacuum measuring devices, vacuum valves, etc.) in the specific space of the furnace cavity to discharge part of the materials in the furnace cavity, so that the pressure in the furnace cavity is less than a standard atmospheric pressure. , the space in the furnace cavity to achieve a vacuum state, which is a vacuum furnace.

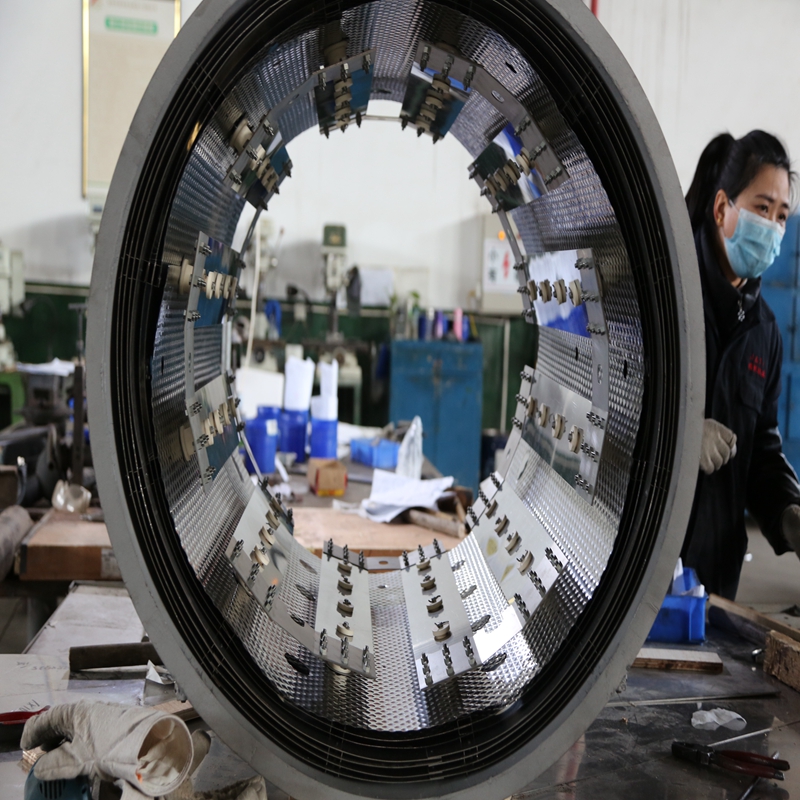

Industrial furnaces and experimental furnaces heated by electric heating elements in a near-vacuum state. Equipment for heating in a vacuum environment. In the furnace chamber sealed by metal casing or quartz glass casing, it is connected with the high vacuum pump system by pipeline. The vacuum degree of the furnace can reach 133×(10-2~10-4)Pa. The heating system in the furnace can be directly heated with silicon carbon rod or silicon molybdenum rod, and can also be heated by high frequency induction. The highest temperature can reach about 2000℃. Mainly used for ceramic firing, vacuum smelting, degassing of electric vacuum parts, annealing, brazing of metal parts, and ceramic and metal sealing, etc.

Advantages of vacuum furnace

It can eliminate the oxidation and decarburization of the workpiece surface during the thermal process, and obtain a clean surface without a metamorphic layer. This is a great improvement in cutting performance for those tools that only grind one side during sharpening (such as twist drills that expose the decarburized layer on the groove surface directly to the cutting edge after grinding).

No pollution to the environment, no need for three waste treatment.

The furnace temperature measurement and monitoring accuracy are significantly improved. The indicated value of the thermocouple reaches ±1.5°C with the furnace temperature. However, the temperature difference between different parts of a large number of workpieces in the furnace is relatively large. If the forced circulation of rare gas is used, the temperature difference can still be controlled within the range of ±5 °C.

High degree of mechatronics. On the basis of improving the accuracy of temperature measurement and control, workpiece movement, air pressure adjustment, power adjustment, etc. can be programmed in advance, and quenching and tempering can be implemented in steps.

The energy consumption is significantly lower than that of a salt bath furnace. The modern advanced vacuum furnace heating chamber adopts thermal insulation walls and barriers made of high-quality thermal insulation materials, which can highly concentrate the electric heating energy in the heating chamber, and the energy saving effect is remarkable.

July 03, 2023

Wyślij je do tym dostawcy

July 03, 2023

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.